Hack Chat 0x01: Introduction to Laser Cutter

-

Steag Center For Smart City Technology is organizing Hack Chat regarding Laser Cutter. The Center is equipped with 150W C02 Laser cutter and Engraver,

In the session, we will look into the working principles and operation workflow the laser machine for cutting and engraving.

The Session exclusively for the Rajagiri School of Engineering & Technology students.

Date: Feb 6th 2020

Time: 5:00 PM to 5:30 PM

Venue: Steag Center For Excellence in Smart City Technologies, KE Block Extension RSETNote: The Session exclusively for the Rajagiri School of Engineering & Technology students.

-

What is Laser Cutter/Engraver?

Laser cutting is a technology that uses a laser to slice materials. While typically used for industrial manufacturing applications, it is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. (Wikipedia) .

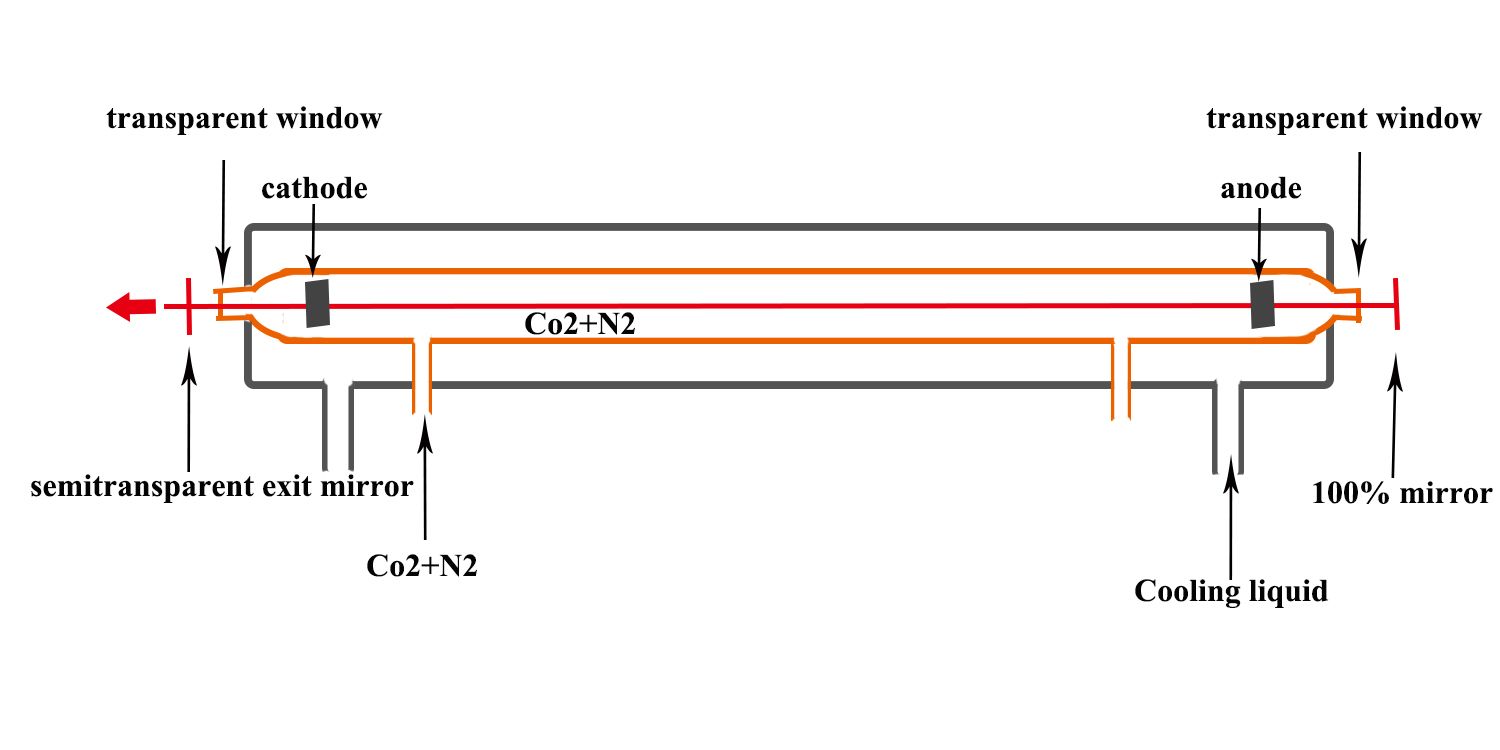

CO2 (Carbon dioxide) Laser?

The carbon dioxide laser (CO2 laser) was one of the earliest gas lasers to be developed. It was invented by Kumar Patel of Bell Labs in 1964,[1] and is still one of the most useful. Carbon dioxide lasers are the highest-power continuous wave lasers that are currently available. They are also quite efficient: the ratio of output power to pump power can be as large as 20%. The CO2 laser produces a beam of infrared light with the principal wavelength bands centring on 9.4 and 10.6 micrometres (μm). (Wikipedia)CO2 Laser Tube :

(img src: http://www.xtlaser.kr/co2-laser-work/)

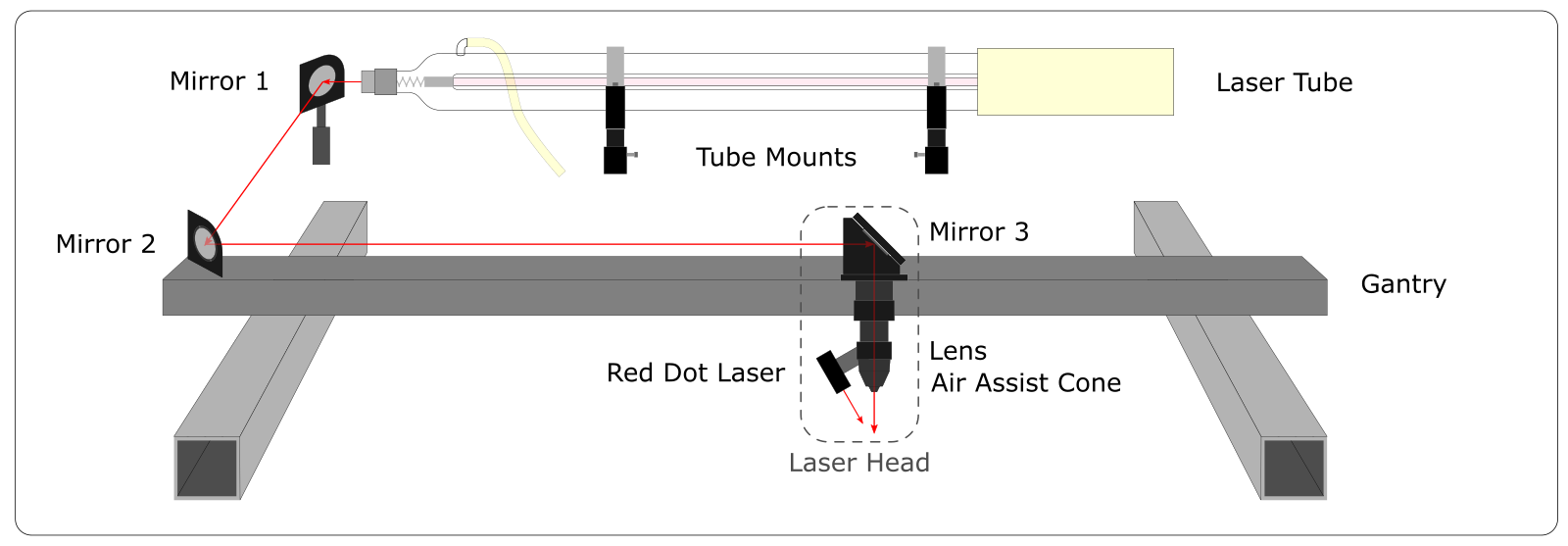

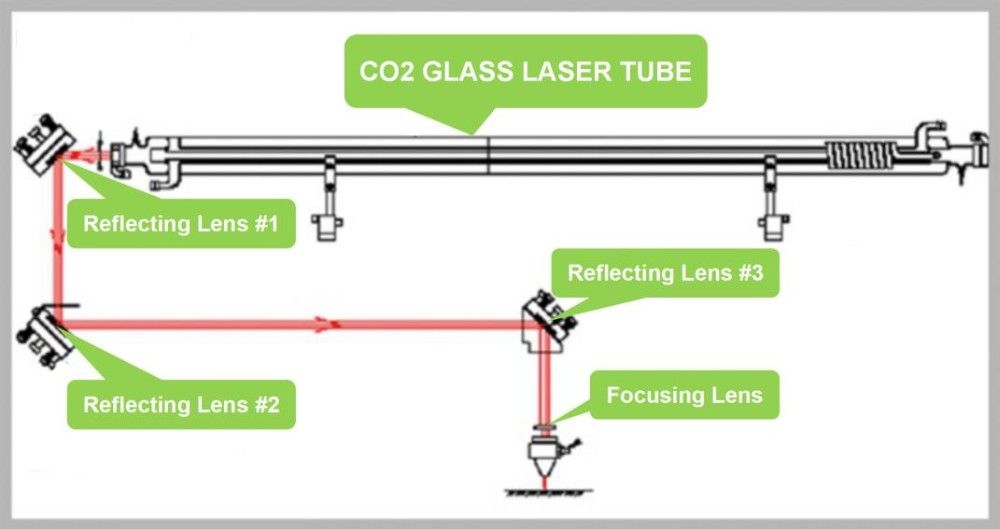

Laser Beam Alignment

(img src: https://smokeandmirrors.store//)

-

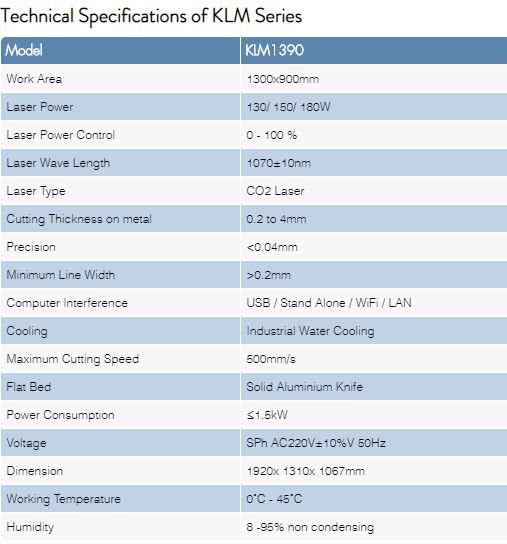

Kavone KLM Serines 150w CO2 Laser Cutter

Features

CO2 metal cutting is the low-cost metal cutting solution. Can be used for metal and non-metal cutting

Applications

Cutting on various materials such as Stainless steel, carbon steel, ABS double-coated sheet, Acrylic, Cloth, Leather, Plastic, paper, wood, Rubber, etc.

-

Photos

-

Really insightful on how to use the laser cutter, especially in projects based application

Thanks Salman