@zainmuhammed

this is the code

#include <Arduino.h>

#include <U8x8lib.h>

#include <TinyGPS++.h>

#include <SoftwareSerial.h>

static const int RXPin = 1, TXPin = 2;

static const uint32_t GPSBaud = 9600;

// The TinyGPS++ object

TinyGPSPlus gps;

// The serial connection to the GPS device

SoftwareSerial ss(RXPin, TXPin);

U8X8_SSD1306_128X64_NONAME_HW_I2C u8x8(/*reset=*/U8X8_PIN_NONE);

// U8X8_SSD1306_128X64_NONAME_SW_I2C u8x8(/*clock=*/ SCL, /*data=*/ SDA, /*reset=*/ U8X8_PIN_NONE); // OLEDs without Reset of the Display

static char recv_buf[512];

static bool is_exist = false;

static bool is_join = false;

static int led = 0;

static int at_send_check_response(char *p_ack, int timeout_ms, char *p_cmd, ...) {

int ch;

int num = 0;

int index = 0;

int startMillis = 0;

va_list args;

char cmd_buffer[256]; // Adjust the buffer size as needed

memset(recv_buf, 0, sizeof(recv_buf));

va_start(args, p_cmd);

vsprintf(cmd_buffer, p_cmd, args); // Format the command string

Serial1.print(cmd_buffer);

Serial.print(cmd_buffer);

va_end(args);

delay(200);

startMillis = millis();

if (p_ack == NULL) {

return 0;

}

do {

while (Serial1.available() > 0) {

ch = Serial1.read();

recv_buf[index++] = ch;

Serial.print((char)ch);

delay(2);

}

if (strstr(recv_buf, p_ack) != NULL) {

return 1;

}

} while (millis() - startMillis < timeout_ms);

return 0;

}

static void recv_prase(char *p_msg) {

if (p_msg == NULL) {

return;

}

char *p_start = NULL;

int data = 0;

int rssi = 0;

int snr = 0;

p_start = strstr(p_msg, "RX");

if (p_start && (1 == sscanf(p_start, "RX: \"%d\"\r\n", &data))) {

Serial.println(data);

u8x8.setCursor(2, 4);

u8x8.print("led :");

led = !!data;

u8x8.print(led);

if (led) {

digitalWrite(LED_BUILTIN, LOW);

} else {

digitalWrite(LED_BUILTIN, HIGH);

}

}

p_start = strstr(p_msg, "RSSI");

if (p_start && (1 == sscanf(p_start, "RSSI %d,", &rssi))) {

u8x8.setCursor(0, 6);

u8x8.print(" ");

u8x8.setCursor(2, 6);

u8x8.print("rssi:");

u8x8.print(rssi);

}

p_start = strstr(p_msg, "SNR");

if (p_start && (1 == sscanf(p_start, "SNR %d", &snr))) {

u8x8.setCursor(0, 7);

u8x8.print(" ");

u8x8.setCursor(2, 7);

u8x8.print("snr :");

u8x8.print(snr);

}

}

void setup(void) {

u8x8.begin();

u8x8.setFlipMode(1);

u8x8.setFont(u8x8_font_chroma48medium8_r);

ss.begin(GPSBaud);

Serial.begin(GPSBaud);

pinMode(LED_BUILTIN, OUTPUT);

digitalWrite(LED_BUILTIN, HIGH);

Serial1.begin(9600);

Serial.print("E5 LORAWAN TEST\r\n");

u8x8.setCursor(0, 0);

if (at_send_check_response("+AT: OK", 100, "AT\r\n")) {

is_exist = true;

at_send_check_response("+ID: DevEui", 1000, "AT+ID=DevEui,\"xxxxx\"\r\n"); // replace 'xxxxxxxxxxxxx' with your DevEui

at_send_check_response("+ID: AppEui", 1000, "AT+ID=AppEui,\"xxxxxxx\"\r\n"); // replace 'xxxxxxxxxxxxx' with your AppEui

at_send_check_response("+KEY: APPKEY", 1000, "AT+KEY=APPKEY,\"xxxxxxxxx\"\r\n"); // replace 'xxxxxxxxxxxxx' with your AppKey

at_send_check_response("+ID: DevAddr", 1000, "AT+ID=DevAddr\r\n");

at_send_check_response("+ID: AppEui", 1000, "AT+ID\r\n");

at_send_check_response("+MODE: LWOTAA", 1000, "AT+MODE=LWOTAA\r\n");

at_send_check_response("+DR: IN865", 1000, "AT+DR=IN865\r\n"); // Change FREQ as per your location

at_send_check_response("+CH: NUM", 1000, "AT+CH=NUM,0-2\r\n");

at_send_check_response("+CLASS: C", 1000, "AT+CLASS=A\r\n");

at_send_check_response("+PORT: 8", 1000, "AT+PORT=8\r\n");

delay(200);

u8x8.setCursor(5, 0);

u8x8.print("LoRaWAN");

is_join = true;

} else {

is_exist = false;

Serial.print("No E5 module found.\r\n");

u8x8.setCursor(0, 1);

u8x8.print("unfound E5 !");

}

u8x8.setCursor(2, 4);

u8x8.print("led :");

u8x8.print(led);

}

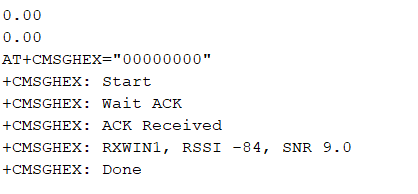

void loop(void) {

if (is_exist) {

int ret = 0;

if (is_join) {

ret = at_send_check_response("+JOIN: Network joined", 12000, "AT+JOIN\r\n");

if (ret) {

is_join = false;

} else {

at_send_check_response("+ID: AppEui", 1000, "AT+ID\r\n");

Serial.print("JOIN failed!\r\n\r\n");

delay(5000);

}

} else {

gps.encode(ss.read());

float a=gps.location.lat();

float b=gps.location.lng();

Serial.println(a);

Serial.println(b);

char cmd[128];

sprintf(cmd, "AT+CMSGHEX=\"%04X%04X\"\r\n", (float)a,(float)b);

ret = at_send_check_response("Done", 5000, cmd);

if (ret) {

recv_prase(recv_buf);

} else {

Serial.print("Send failed!\r\n\r\n");

}

delay(5000);

}

} else {

delay(1000);

}

}